Controlling Quality at Every Stage

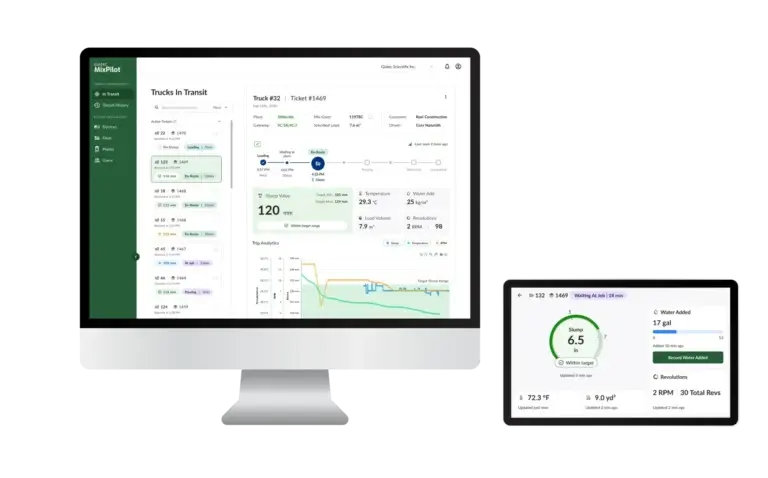

Without visibility during transit, quality control becomes a guessing game. MixPilot gives your team live access to key concrete metrics through web-based and mobile applications, providing actionable insights that help you catch quality issues early and deliver on schedule.

How Does MixPilot Work?

MixPilot is a powerful, non-invasive, self-calibrating hardware solution designed for precise, real-time monitoring from plant to pour. Using a wireless hydraulic pressure sensor together with a proprietary magnetic drum sensor, it delivers highly accurate and reliable slump calculations. These measurements are seamlessly transmitted to a wireless gateway, where Giatec’s patented algorithms automatically calibrate the mix results, delivering key metrics on slump, temperature, and volume.

Lead with Quality

Maximize profits by investing in quality with every load. Access reliable slump, volume, and temperature data in-transit with a fully integrated system to your operating systems.

Empower with Accuracy

Make every driver your best driver with accurate, real-time data at their fingertips. Allow full control for each ‘factory on wheels’ for both the driver and their enablers across operations.

Install with Ease

Enjoy hassle-free installation featuring a robust, non-invasive, wireless, and magnetic setup that requires no manual calibration. Get your system up and running in just 15 minutes.

Ready to Transform Your Concrete Quality From Plant to Pour?

Book your free MixPilot consultation today and discover how the industry's most advanced slump monitoring system is helping top producers improve quality, reduce waste, and deliver with confidence.